Since 1876, PASEK has earned a reputation for expertise in mechanical locking hardware and key systems.

The Following Information is Provided Courtesy of LCN

Selecting a Door Closer

Door closers are available in two styles—concealed or surface mounted. When choosing a closer style, consideration should be given to the type of door being controlled, frame conditions, aesthetics and control features needed. Closers concealed in the head frame over the door are out of sight and out of the way. They are protected from dirt, and easy to reach for regulation without any moving parts. Closers are available for frame sections as thin as 1-3/4″.

Closers located within the door itself are also hidden and protected. They work well on interior doors and are economical.

For surface mounted closers location is also a consideration. Closers on doors along a corridor should be located on the room side of the door so they are out of sight. Closers should be placed on the inside of exterior doors for protection and aesthetics.

Heavy duty door closers should be used in:

- Schools or public buildings where hard usageis expected.

- Exterior doors.

- -Doors subject to drafts, winds or air pressure differential.

- High frequency doors such as those in malls, stores or tenancies.

Degree of Opening

Three basic rules apply to maximum degree of opening:

- It is best to let the door swing as far as it can swing freely. Some closers are mounted in different locations for different degrees of opening.

- Use a mechanical stop when a door can not swing 180º or at the selected hold-open point of a double lever arm system. The mechanical stop can be mounted on the floor, wall or overhead.

- The closer should be positioned so back check takes place well in advance of the stop position to cushion the opening swing and prevent damage from an abrupt stop.

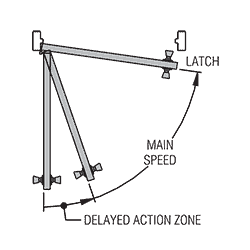

Delayed Action Function

Many closers can be ordered with delayed action function. Delayed action is a special hydraulic circuit that provides additional time to pass through a door. A regulating screw controls the closing speed from maximum opening through approximately 75º. After that the normal closing speed resumes. Delayed action is not available with single lever arm closers.

Door Dimensions

The width of the door is the main consideration in determining the correct closer size. Size here refers to the minimum spring power (closing force) generated by the closer. If a door is of exceptional height, weight, special construction, or if drafts and air pressure differentials exist, increased closer power should be considered. Door thickness may be a factor. A concealed-inthe- door closer should not be used in a hollow metal door less than 1-1/2″ thick or a wood door less than 1-3/4″ thick. Exceptionally thick doors can affect hinge and pivot centers to the extent that closer functions and geometry are also affected.The depth of the door’s top rail is important to nearly every closer installation. Narrow top rails may require plates to successfully mount the closer. An insufficient top rail in flush, hollow or composition filled doors may make concealed-in-the-door installation impractical.

Proper Door Control

Practically every door in modern commercial, industrial and institutional buildings is opened by the person passing through and closed by a mechanical door closer which should keep the door under orderly control at all times. The power to close the door is generated by springs inside the closer. The speed of the door closing swing is controlled by regulated hydraulic circuits.

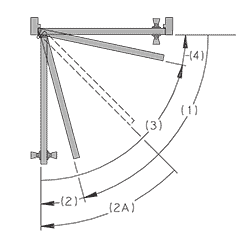

The diagram shows the main stages in correct door operation.

- On the opening swing, the door closer’s function is to let the door open easily, except at the end of the swing where back check is applied.

- Back check is a feature that cushions the opening swing to prevent the door from slamming into the stop. Special closers designed for potentially abusive applications begin the back check function much earlier (2A).

- Through the long closing arc, a uniform, reasonable (main) speed should be maintained.

- The latching arc brings the door to a quiet, secure close.

Determining the Hand of a Door

Some door closers are handed. When approaching a door from the push side, if hinged on the left, it is a left hand door; if hinged on the right, it is a right hand door.

For purposes of handing door closers, right hand reverse bevel and left hand are identical; left hand reverse and right hand are identical. Some corner bracket installations require a closer opposite handed than the hand of the door.

Plates, Brackets, Adapters, Special Pieces

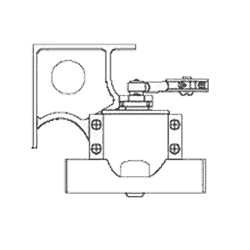

Corner brackets were once the only satisfactory way to install a closer on the push side of a door. They still meet special requirements which other mountings do not satisfy.

Specialized brackets, adapters and parallel arm shoes are available to simplify the installation of closers with a variety of frame and door conditions.